I wanted to make this a general topic although I got my parts from a specific vehicle.

Since this is my first lab I wanted to question how to go about doing this setup and share the discussion for anyone else looking to build a lab from a donor vehicle.

In this particular case I have a number of components from a 2001 S10 Blazer.

Over head Console (With DIC)

PCM

BCM

Keyfob and receiver

Cellular radio and control box

Instrument Panel

Control box from right front kick panel (Not sure what it was but remember seeing it mentioned in the factory docs so I grabbed it.)

ODII connector

All the buttons from the dash

Most of the wireharness from the ceiling (not including lighting), most of the wiring from the dash. (Not including the stuff mounted behind hard to get pannels or running through the fire wall. ) I grabbed the under hood fuse panel, the fuse panel from the left side of the dash and all of the relays from a panel behind the dash fuse panel.

Most of the units I cut the wiring from the plug leaving as much as I could. The in dash harness and most of the ceiling harness is in tact.

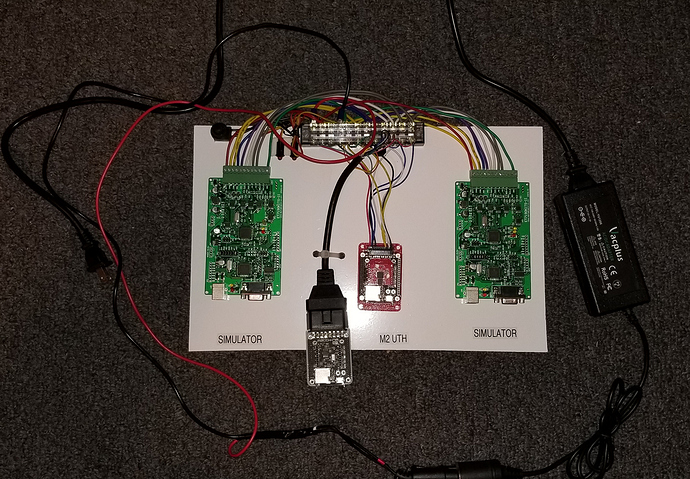

So with all this and my Radio Shack 13.8v / 19amp power supply I plan to make a lab. Will initially test with my STN based ODBII to USB adapter then move to building the j1850 VPW drivers to communicate via the M2.

So I am assuming I should start by wiring the BCM and IP to the ODBII connector and see if I can communicate with them? Then once I have that working add the PCM and the other computerized modules I have and wiring the switches into the BCM?

This vehicle apparently doesn’t have the significant number of modules that my '03 Truck does and everything is instead done via the BCM. As I write this I think I probably should have grabbed the relay box that had all the relays in it but maybe I won’t need them or can go a different route.

Suggestions? Comments? I am sure I am not the only one building a lab to use to learn or program the M2?

Thanks for participating! Grabbing my board and will start mounting stuff soon.

Rodney

. I’m hoping you can get me going in the right direction.

. I’m hoping you can get me going in the right direction.